Randall Manufacturing Inc. is a producer of geotextile products for uses in filtration, drainage, separation and reinforcement application.

Non-Woven Geotextile

Our nonwoven needle-punched geotextiles are manufactured using high quality synthetic fibers (Polypropylene/Polyester). Our careful selection of these synthetic fibers allow us to make a strong, resilient, and robust product. These products endure ultraviolet deterioration, decay, biological degradation, and are unaffected by commonly encountered soil chemicals.

- Preserving the structural of roadway

- Soil Reinforcement

- Bank protection

- Coastal Protection

- Foundation drains

- Gabion Lining

- Retaining Walls

- Drop Structure

- Ditch Lining

- Revetments

- Channel Linings

- Lighter Coastal Applications

- Access Routes

- Industrial Yards

- Logging Roads

- Railway Track Rehabilitation

- New Railway Track Construction

- Rockfill Structures

- Dykes

- Energy Dissipators

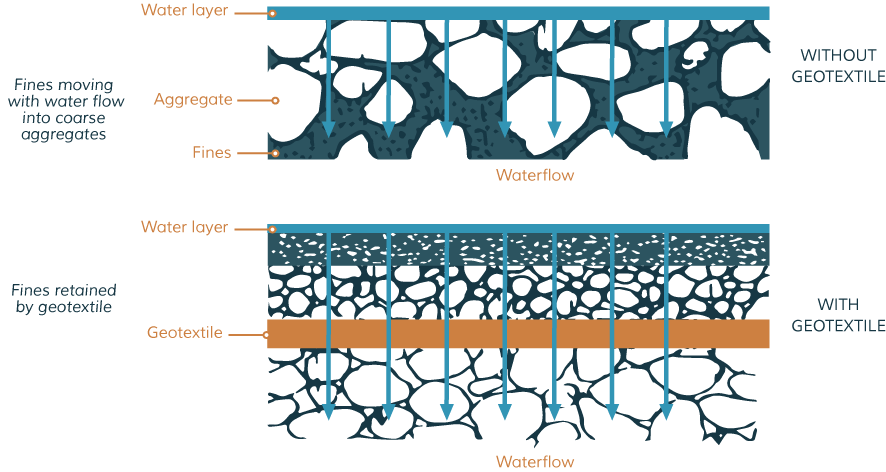

Filtration

Geotextile is a filter in that it permits the flow of liquids. At the same time it prevents the passage of soil particles which can cause settlement. The filtration opening size (FOS) within the geotextile is chosen to aid against blocking and clogging.

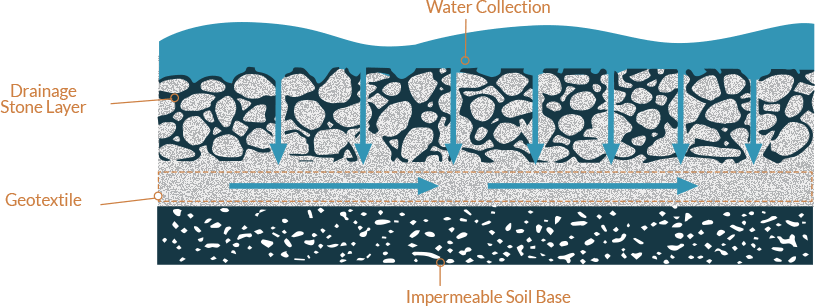

Drainage

Ground drains are put in place as a way of preventing or intercepting water flow. It is a means of which to reduce a possibility of a rise in pore water pressure. Often these drains are vertically sided trenches that are lined with a geotextile, and then they are filled with coarse gravel. This generates a zone (in the soil particles that remain) to bridge over the pores in the geotextile and retain smaller particles. Thus, a natural graded filter is formed that will assist in preventing additional washout of fine particles.

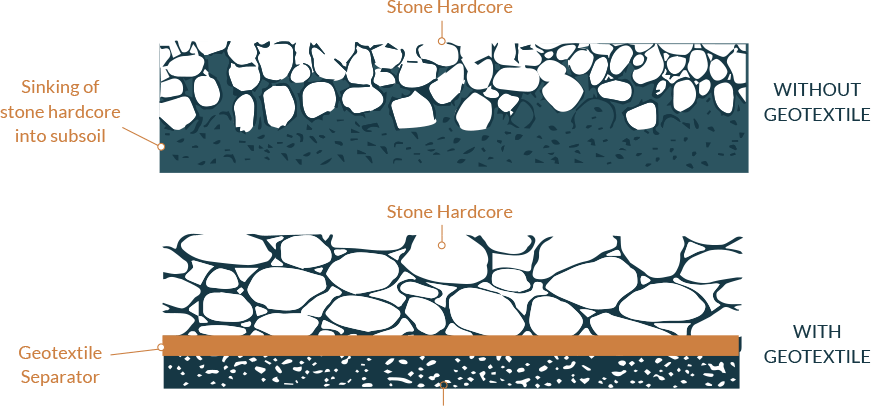

Separation

Geotextile products assist in separating solids from liquids, which becomes an essential part of numerous industrial processes. Geotextile is known as a separator in that it prevents the intermixing of coarse and fine soil materials. At the same time, it allows a free flow of liquids across the geotextile. This will help to maintain the purity of the product, assists in recovering precious materials, saves energy and leads to improvements in process efficiency.

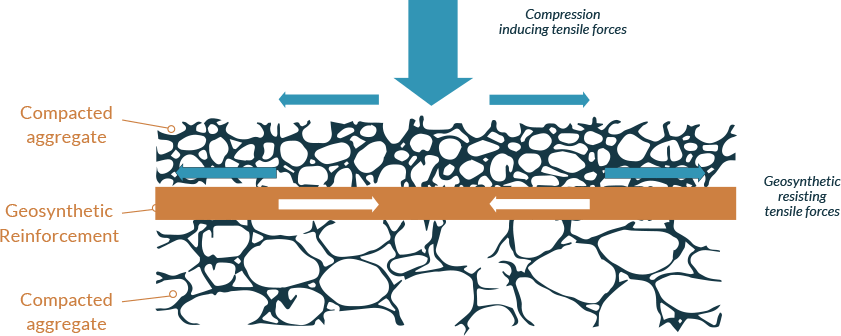

Reinforcement

Synthetic Fibers such as Polypropylene/Polyester are used in geotextiles to extend the range of application for textiles and their uses in soil reinforcement.

- RM-110

- RM-130 - 3oz

- RM-150 - 4oz

- RM-170 - 4.5oz

- RM-200 - 6oz

- RM-240 - 7oz

- RM-300 - 8oz

- RM-350 - 10oz

- RM-400 - 12oz

- RM-550 - 16oz

Woven Geotextiles

Slit Film

- Woven Geotextile is made of Durable Polypropylene Yarns Woven for Dimensional Stability and Strength.

- The Slit film Woven Fabric Strength is Suitable for Encapsulation and Fabrication in Both Temporary and Permanent Structures

- Factory-made to ensure is it Resistant to Chemical and Biological Environments

- It’s unique Low Elongation Fabric Properties Limit Construction Damage Such as Tearing or Puncturing

- Roll Sizes for Woven Slit Film Products come in industrial standards

Woven Slit Film Geotextile provide stabilization and separation benefits preventing base aggregates from migrating into subgrade soil. Woven Slit film products provide an economical solution to civil engineering projects.

Applications

- Separation

- Separation

- Stabilization

Agro Textiles

- RM-VineFit (standard roll sizes)

- RM-GC Protects your fields from weed growth. Available in standard geotextile roll sizes.

Vine Fit

Vine-fit textile will protect grape and wine industry investments from freeze injury.

Non-woven textile can reduce and eliminate physically damage to vines. They can also increase and sustain crop yields compared to buried veins.

Vines covered in non-woven textile have shown improved general appearance and healthier buds and canes. As well as consistent growth.

Ground Cover

Randalls ground cover textile prevents weed growth around your valuable crop while ensuring sufficient drainage and exceptional strength.